Ethanol Sensor User Manual

Order Code: ETH-BTA

The Ethanol Sensor measures the concentration of ethanol in the air above an aqueous sample. This sensor can be used in a wide range of tests and experiments in biological, agricultural, food, and environmental sciences.

- Determine the rate of ethanol production during fermentation.

- Measure the discrete amount of ethanol in a given sample.

- Investigate which sugars yeast can ferment.

- Identify specific organisms that can utilize ethanol fermentation as a metabolic pathway.

Note: Vernier products are designed for educational use. Our products are not designed nor are they recommended for any industrial, medical, or commercial process such as life support, patient diagnosis, control of a manufacturing process, or industrial testing of any kind.

What's Included

- Ethanol Sensor

- 250 mL Nalgene Bottle

- #6 Stopper

- Replacement cap assembly

- Plumber's Tape

Compatible Software

Choose a platform below to see its compatibility requirements.LabQuest

Interface LabQuest App LabQuest 3 Full support LabQuest 2 Full support LabQuest Full support Computers

Software Interface Graphical Analysis Graphical Analysis (Web App) Logger Pro (discontinued) Logger Lite (discontinued) LabQuest Mini Full support Full support Full support Full support LabQuest 3 Full support Full support Full support Incompatible LabQuest 2 Full support Full support Full support Full support LabQuest Stream Full support 1 Full support 1 Partial support 2 Full support 1 LabQuest Full support Full support Full support Full support LabPro Incompatible Incompatible Full support Full support Compatibility Notes

Chromebook

Software Interface Graphical Analysis (Web App) LabQuest Mini Full support LabQuest 3 Full support LabQuest 2 Full support LabQuest Stream Full support 1 LabQuest Full support Compatibility Notes

iOS

Software Interface Graphical Analysis Graphical Analysis GW LabQuest Stream Full support Full support LabQuest 3 Full support 1 Full support 1 LabQuest 2 Full support 1 Full support 1 Compatibility Notes

Android

Software Interface Graphical Analysis Graphical Analysis GW LabQuest Stream Full support Incompatible LabQuest 3 Full support 1 Full support 1 LabQuest 2 Full support 1 Full support 1 Compatibility Notes

Arduino

Software Interface Arduino Vernier Arduino® Interface Shield Full support 1 Compatibility Notes

LabVIEW

Software Interface NI LabVIEW SensorDAQ Full support 1 Vernier myDAQ Adapter Full support 1 2 LabQuest Mini Full support LabQuest Stream Full support LabQuest 3 Full support LabQuest 2 Full support LabQuest Full support Compatibility Notes

Texas Instruments

Software Interface EasyData DataQuest TI-Nspire Software CBL 2 Full support 1 Incompatible Incompatible LabPro Full support 1 Incompatible Incompatible TI-Nspire Lab Cradle Incompatible Full support Full support Compatibility Notes

Getting Started

- Connect the sensor to the interface (LabQuest Mini, LabQuest 3, etc.).

- Start the appropriate data-collection software (Vernier Graphical Analysis®, LabQuest® App, or Logger Pro™) if not already running, and choose New from File menu. The software will identify the sensor and load a default data collection setup. Note: It is necessary to warm up the Ethanol Sensor for 5 minutes before taking readings. To warm up the probe, simply leave it connected to the interface with the data-collection software running.

- You are now ready to collect data.

If you are collecting data using a Chromebook™, mobile device such as iPad® or Android™ tablet, or a Vernier wireless sensor or interface, please see the following link for up-to-date connection information:

Videos

Calibrating the Sensor

It may not be necessary to perform a calibration when using the Ethanol Sensor in the classroom. If your experiment or application is evaluating the rate of ethanol production, such as determining fermentation rates with yeast, or the relative change in ethanol concentration, then the stored calibration works well.

For quantitative analysis of ethanol samples, it is best to use a two-point calibration to improve accuracy. The two points you choose for your calibration will depend on the expected amount of ethanol in your sample. For best results at low concentrations (0.1–1%), calibrate using 1% and 0.1% ethanol. For best results at high concentrations (1.0–3.0%), calibrate using 3.0% and 1% ethanol. If you are measuring an intermediate range you can also calibrate using 0.2% and 2.0% ethanol. Use the higher standard first for any calibration.

The instructions for calibration are dependent on the data collection interface you are using.

- For instructions for Ethanol Sensor calibration using Graphical Analysis with a Chromebook, see www.vernier.com/til/3631

- For instructions for Ethanol Sensor calibration using Graphical Analysis with an iOS or Android device, see www.vernier.com/til/3630

- For instructions for Ethanol Sensor calibration using LabQuest App, see www.vernier.com/til/3394

- For instructions for Ethanol Sensor calibration using Logger Pro computer software, see www.vernier.com/til/2341

Making Ethanol Standards for Calibration

To make solutions for the ethanol calibration, you will need to dilute fresh, stock ethanol to the appropriate concentration. Denatured ethanol or non-denatured, grain ethanol may be used. Ethanol that is 70% is more stable than 95%. For the most accurate results, use a volumetric flask to make the standards. Use the following equation to guide you:

C1V1 = C2V2

- C1 is the concentration of the stock solution (typically 70% or 95%).

- V1 is the amount of stock solution to be added (you will solve for this).

- C2 is the desired concentration in %.

- V2 is the total final volume.

- V2 – V1 = amount of distilled water to add to the stock solution

It may be necessary to do a serial dilution in order to get the precision you need for your standards. The following table shows an example of a serial dilution to make 0.1% ethanol starting with 70% ethanol.

|

Original concentration of ethanol |

Amount of ethanol to add (mL) |

Final volume (ethanol and water) (mL) |

Final concentration |

|

70% |

14.3 |

100.0 |

10% |

|

10% |

10.0 |

100.0 |

1% |

|

1% |

10.0 |

100.0 |

0.1% |

Specifications

|

Range |

0% to 3% |

|

Accuracy (factory calibration) Accuracy (custom calibration) |

±1.5% at 3%

|

|

Resolution |

0.02% from 2–3% |

|

Response time |

95% of full scale in 60 seconds |

|

Stored calibration values |

|

Care and Maintenance

Do not wrap the cable tightly around the sensor for storage. Repeatedly doing so can irreparably damage the wires and is not covered under warranty.

The Vernier Ethanol Sensor is neither waterproof, nor is it water resistant and should never be immersed in any liquid. If any liquid gets into the device, disconnect the sensor and allow the device to dry thoroughly before attempting to use the device again. Do not attempt to dry using an external heat source. Note: Damage due to exposure to liquids is not covered under warranty.

Note: It is recommended that you wash the Nalgene bottle by hand. Most dishwashers will melt plastic bottles.

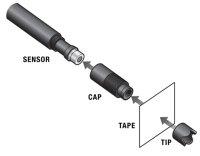

Making a Cap Assembly

The Ethanol Sensor comes with caps that have a membrane installed. You do not need to make a cap assembly using teflon tape, but if you choose to do so, follow the steps below.

- Remove the tip of the cap from the sensor. Discard the tissue paper covering the cap (first use only).

- Cut a 1.5 centimeter piece of plumber's tape (included).

- Cover the cap entirely with the tape and inspect the tape for wrinkles or gaps.

- Place the tip over the tape and verify that it is secure before proceeding.

- Connect the probe following the steps in the Getting Started section of this user manual.

Note: Remove the tape from the cap at the end of the experiment. For best results, use a new piece of tape on each day the sensor is used.

How the Sensor Works

The Vernier Ethanol Sensor uses a metal oxide semiconductor to detect ethanol concentrations in the air. The ethanol vapor reacts with the metal oxide and is consumed in a combustion reaction which reduces the internal resistance of the sensor element. An amplifier is used to convert the change in sensor resistance to a response voltage, which is converted into an appropriate ethanol concentration by the data-collection software. A power function is used for calibration due to the large response range. Note: The sensing element is very sensitive to ethanol vapor and also responds to a wide range of other volatile organic compounds. It also responds to water vapor and carbon dioxide gas to a lesser degree. Built-in temperature, pressure, and humidity compensation are not provided. For best results, calibrate and use at room temperature.

Troubleshooting

- Very important: Do not place the sensor into any liquid. The sensor is designed to measure ethanol vapor above an aqueous sample.

- For best results, allow the sensor to warm up for 5 minutes before taking measurements.

- Built-in temperature, pressure, and humidity compensation are not provided. For best results, calibrate before use and use at room temperature.

- The recommended sampling rate is 1 sample per second or slower for this sensor. Gas must diffuse to the sensing element to detect any changes in concentration. Because diffusion of gasses is a slow process, there can be a delay in response time.

- When using a fermentation chamber, use a clamp or an electrode support to adjust the position of the sensor tip by moving the shaft up or down as necessary.

- The 250 mL Nalgene Bottle and #6 stopper that are included can be used as a fermentation chamber. Wrap the stopper around the sensor shaft, rather than sliding it on or off. Place the probe with the stopper into the bottle, and then gently twist the stopper. Verify that the sensor tip is not immersed in fluid. For best results, place the chamber on a stir plate and use a magnetic stir bar to keep the sample moving.

- To collect data in a controlled environment and also use one of our CO2 gas sensors, we recommend purchasing the BioChamber 2000 (2 L capacity). This BioChamber has a second, grommeted opening so that you can insert two probes at once.

For troubleshooting and FAQs, see www.vernier.com/til/2865

Repair Information

If you have watched the related product video(s), followed the troubleshooting steps, and are still having trouble with your Ethanol Sensor, contact Vernier Technical Support at support@vernier.com or call 888-837-6437. Support specialists will work with you to determine if the unit needs to be sent in for repair. At that time, a Return Merchandise Authorization (RMA) number will be issued and instructions will be communicated on how to return the unit for repair.

Accessories/Replacements

| Item | Order Code |

|---|---|

|

ETH-CAPS |

|

|

ETH-STOP |

|

| Tape for Ethanol Sensor |

ETH-TAPE |

| 250 mL Nalgene Bottle w/Lid |

CO2-BTL |

| BioChamber 2000 |

BC-2000 |

Warranty

Warranty information for this product can be found on the Support tab at www.vernier.com/eth-bta/#support

General warranty information can be found at www.vernier.com/warranty

Disposal

When disposing of this electronic product, do not treat it as household waste. Its disposal is subject to regulations that vary by country and region. This item should be given to an applicable collection point for the recycling of electrical and electronic equipment. By ensuring that this product is disposed of correctly, you help prevent potential negative consequences on human health or on the environment. The recycling of materials will help to conserve natural resources. For more detailed information about recycling this product, contact your local city office or your disposal service.

The symbol, shown here, indicates that this product must not be disposed of in a standard waste container.

The symbol, shown here, indicates that this product must not be disposed of in a standard waste container.

Contact Support

Fill out our online support form or call us toll-free at 1-888-837-6437.