It is possible for a Motion Encoder to incorrectly announce its name to the software, causing the Auto-ID feature to fail. This issue is likely to be intermittent, as it is often caused by a bad connection. If the Motion Encoder Receiver is identified by the data-collection software as a linear position sensor, it will only create a column for position data and show units of mm, rather than setting up columns for position (in units of meters), velocity, and acceleration.

The problem is most likely with the BTD cable on the Motion Encoder Cart Receiver (

Try the following:

- Check the pins on the BTD plug on the Encoder Receiver for debris or corrosion and clean them if necessary.

- If possible, swap the Encoder Receiver for one that works as expected.

- Try the same receiver with a different interface.

If you can determine which piece of the system is responsible for the problem, we can repair or replace that part. Contact Vernier Technical Support to arrange for a repair. If in doubt, we will first service the encoder receiver.

As a short-term workaround when using Logger Pro 3 or LabQuest App, you can manually set up the motion encoder receiver in the software by doing the following:

- From the Sensor Setup screen, choose Motion Encoder Cart from the options on the DIG port. (Make sure you select the same port where the sensor is physically connected DIG1 or DIG2.)

- The software will then set up the appropriate data columns and treat data coming from the Receiver as motion data.

Manual sensor setup is not possible when using Graphical Analysis or Graphical Analysis Pro apps.

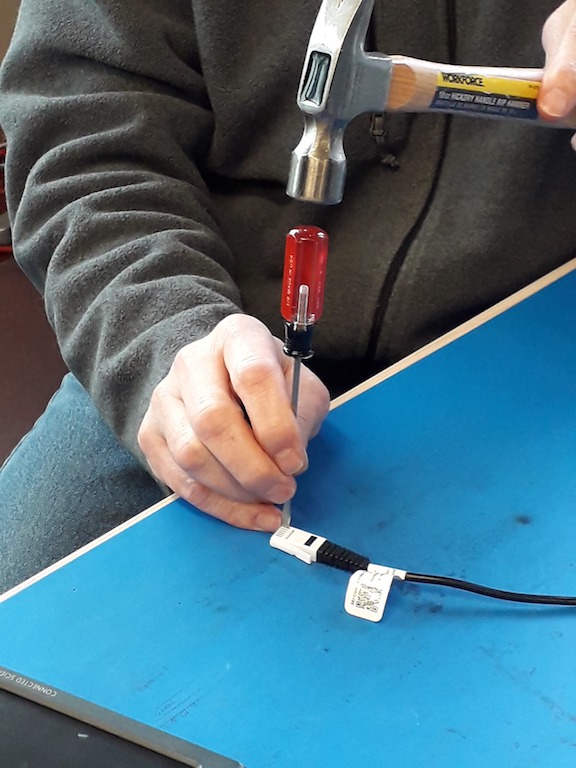

If you experience this issue, but wish to continue using the unit(s) in the short term you may be able to improve the connection by manually crimping the connector. To accomplish this use a small screwdriver and a hammer. Gently tap each of the six wires on the BTD plug as shown below: